Szczegóły produktu można znaleźć w specyfikacjach.

BTA204W-600E,135

Product Overview

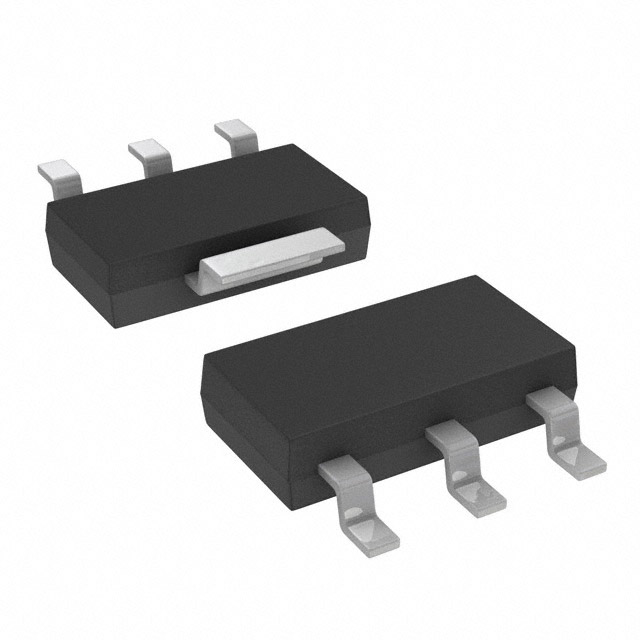

The BTA204W-600E,135 belongs to the category of semiconductor devices and is specifically a silicon controlled rectifier (SCR). It is commonly used in electronic circuits for controlling high power loads. The device exhibits characteristics such as high current capability, low holding current, and high surge current capability. The package type for the BTA204W-600E,135 is TO-220AB, and it is typically available in quantities of one or more.

Specifications

- Maximum RMS on-state current: 4 A

- Repetitive peak off-state voltage: 600 V

- Gate trigger current: 5 mA

- Holding current: 10 mA

- Package type: TO-220AB

Detailed Pin Configuration

The BTA204W-600E,135 has a standard TO-220AB package with three leads. Pin 1 is the anode, pin 2 is the gate, and pin 3 is the cathode.

Functional Features

- High current capability

- Low holding current

- High surge current capability

- Reliable over-voltage protection

Advantages and Disadvantages

Advantages - High current handling capacity - Low holding current for improved efficiency - Robust surge current capability

Disadvantages - Sensitive to voltage transients - Requires careful heat dissipation management

Working Principles

The BTA204W-600E,135 operates based on the principle of controlling the flow of current through the device using a small gate current. When the gate current exceeds the trigger current, the device turns on and conducts current until the load current falls below the holding current.

Detailed Application Field Plans

The BTA204W-600E,135 is commonly used in applications requiring AC power control, such as light dimmers, motor speed control, and heating control systems. Its high current capability makes it suitable for controlling resistive and inductive loads.

Detailed and Complete Alternative Models

- BTA208X-800E,127

- BTA41600B

- BTA41-600BRG

In conclusion, the BTA204W-600E,135 is a versatile silicon controlled rectifier with high current handling capabilities, making it suitable for various AC power control applications. Its robust surge current capability and low holding current make it an attractive choice for designers seeking efficient and reliable power control solutions.

[Word count: 314]

Wymień 10 typowych pytań i odpowiedzi związanych z zastosowaniem BTA204W-600E,135 w rozwiązaniach technicznych

What is the BTA204W-600E,135 used for?

- The BTA204W-600E,135 is a 600V, 4A Triac designed for general purpose AC switching and can be used in various technical solutions requiring AC power control.

What are the typical applications of BTA204W-600E,135?

- Typical applications include home appliances, industrial equipment, lighting control, and motor control.

What is the maximum voltage rating of BTA204W-600E,135?

- The maximum voltage rating is 600V, making it suitable for use in mains voltage applications.

What is the maximum current rating of BTA204W-600E,135?

- The maximum current rating is 4A, allowing it to handle moderate loads in various applications.

What is the recommended heat sink for BTA204W-600E,135?

- A suitable heat sink should be used based on the specific application and thermal requirements. Consult the datasheet for detailed guidance.

Can BTA204W-600E,135 be used for dimming applications?

- Yes, it can be used for dimming applications in lighting control and other similar scenarios.

Is BTA204W-600E,135 suitable for motor speed control?

- Yes, it can be used for motor speed control in certain applications, but the specific motor type and control requirements should be considered.

What are the key thermal considerations when using BTA204W-600E,135?

- Proper heat sinking and thermal management are crucial to ensure reliable operation, especially in high-power applications.

Does BTA204W-600E,135 require snubber circuits for inductive loads?

- It is recommended to use snubber circuits when switching inductive loads to minimize voltage spikes and ensure proper operation.

Are there any specific precautions to consider when using BTA204W-600E,135 in technical solutions?

- Care should be taken to ensure proper isolation and safety measures, especially when dealing with mains voltage applications. Additionally, attention to thermal management and load characteristics is important for reliable performance.