Szczegóły produktu można znaleźć w specyfikacjach.

DRV8871DDAR

Product Overview

Category: Motor Driver IC

Use: DRV8871DDAR is a motor driver integrated circuit that provides an easy-to-use solution for driving brushed DC motors.

Characteristics: It offers high efficiency, low power dissipation, and robust protection features.

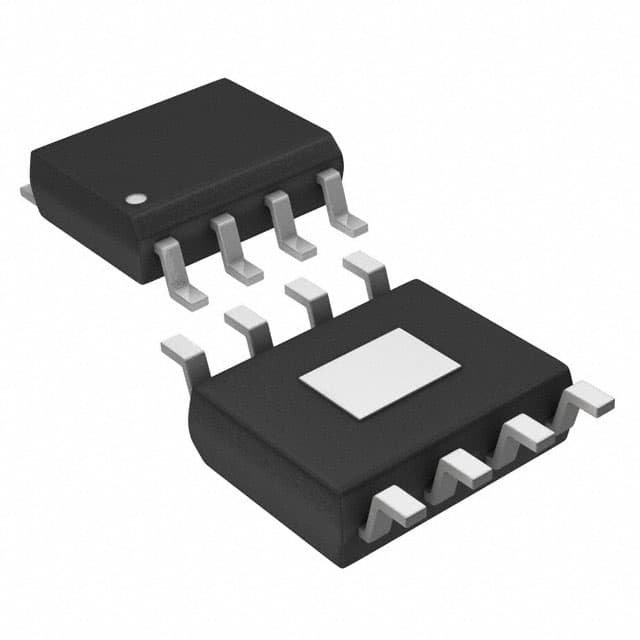

Package: DRV8871DDAR comes in a small surface-mount package.

Essence: This motor driver IC is designed to control the speed and direction of brushed DC motors in various applications.

Packaging/Quantity: DRV8871DDAR is typically sold in reels or tubes, with a quantity of 2500 units per reel.

Specifications

- Operating Voltage Range: 3.6V to 36V

- Continuous Output Current: Up to 3.6A

- Peak Output Current: Up to 7.2A

- Number of Outputs: 1

- Control Interface: PWM, IN/IN

- Fault Protection Features: Overcurrent, Overtemperature, Undervoltage Lockout

Pin Configuration

The DRV8871DDAR has the following pin configuration:

- VCC - Power supply voltage input

- GND - Ground reference

- OUT - Motor output terminal

- IN1 - Input 1 for controlling motor direction

- IN2 - Input 2 for controlling motor direction

- PWM - Pulse Width Modulation input for controlling motor speed

- FAULT - Fault detection output

- EN - Enable input for turning on/off the motor driver

Functional Features

- High-efficiency H-bridge motor driver

- Bidirectional control of brushed DC motors

- Adjustable motor speed through PWM input

- Robust fault protection features for safe operation

- Low-power sleep mode for energy conservation

- Thermal shutdown protection to prevent overheating

Advantages and Disadvantages

Advantages: - High efficiency leads to reduced power dissipation - Robust fault protection ensures safe operation - Compact package size allows for space-saving designs - Wide operating voltage range provides flexibility in various applications

Disadvantages: - Limited to driving brushed DC motors only - Requires external components for proper operation - Higher cost compared to basic motor driver solutions

Working Principles

The DRV8871DDAR operates on the principle of pulse width modulation (PWM) control. The PWM input signal determines the duty cycle, which in turn controls the average voltage applied to the motor. By adjusting the duty cycle, the speed of the motor can be varied. The direction of rotation is controlled by the IN1 and IN2 inputs, which determine the polarity of the voltage applied to the motor terminals.

Detailed Application Field Plans

The DRV8871DDAR finds applications in various fields, including:

- Robotics: Controlling the movement of robotic arms and wheels.

- Automotive: Powering window regulators, seat adjusters, and windshield wipers.

- Industrial Automation: Driving conveyor belts, pumps, and fans.

- Home Appliances: Operating vacuum cleaners, blenders, and electric shavers.

- Consumer Electronics: Controlling camera lens movements, disk drives, and printers.

Detailed and Complete Alternative Models

- L298N - Dual H-Bridge motor driver IC with similar specifications.

- TB6612FNG - Compact motor driver IC with built-in protection features.

- SN754410 - Quadruple half-H driver IC suitable for driving multiple motors simultaneously.

These alternative models offer similar functionality and can be considered as alternatives to DRV8871DDAR based on specific application requirements.

Word count: 527 words

Wymień 10 typowych pytań i odpowiedzi związanych z zastosowaniem DRV8871DDAR w rozwiązaniach technicznych

Sure! Here are 10 common questions and answers related to the application of DRV8871DDAR in technical solutions:

Q1: What is DRV8871DDAR? A1: DRV8871DDAR is a motor driver IC (integrated circuit) designed for driving brushed DC motors.

Q2: What is the maximum voltage that DRV8871DDAR can handle? A2: DRV8871DDAR can handle a maximum voltage of 40V.

Q3: What is the maximum continuous current that DRV8871DDAR can deliver? A3: DRV8871DDAR can deliver a maximum continuous current of 3.6A.

Q4: Can DRV8871DDAR drive both clockwise and counterclockwise rotations of a motor? A4: Yes, DRV8871DDAR can drive both clockwise and counterclockwise rotations of a motor.

Q5: Does DRV8871DDAR have built-in protection features? A5: Yes, DRV8871DDAR has built-in protection features such as overcurrent protection, undervoltage lockout, and thermal shutdown.

Q6: Can DRV8871DDAR be controlled using PWM signals? A6: Yes, DRV8871DDAR can be controlled using PWM (Pulse Width Modulation) signals for speed control.

Q7: What is the typical operating frequency range of DRV8871DDAR? A7: The typical operating frequency range of DRV8871DDAR is between 0Hz and 100kHz.

Q8: Can DRV8871DDAR be used with microcontrollers or Arduino boards? A8: Yes, DRV8871DDAR can be easily interfaced with microcontrollers or Arduino boards for motor control applications.

Q9: Is DRV8871DDAR suitable for battery-powered applications? A9: Yes, DRV8871DDAR is suitable for battery-powered applications as it has a low quiescent current and can operate at low voltages.

Q10: Are there any application examples where DRV8871DDAR can be used? A10: Yes, DRV8871DDAR can be used in various applications such as robotics, drones, home automation, automotive systems, and industrial equipment.

Please note that these answers are general and may vary depending on the specific requirements and use cases.