Szczegóły produktu można znaleźć w specyfikacjach.

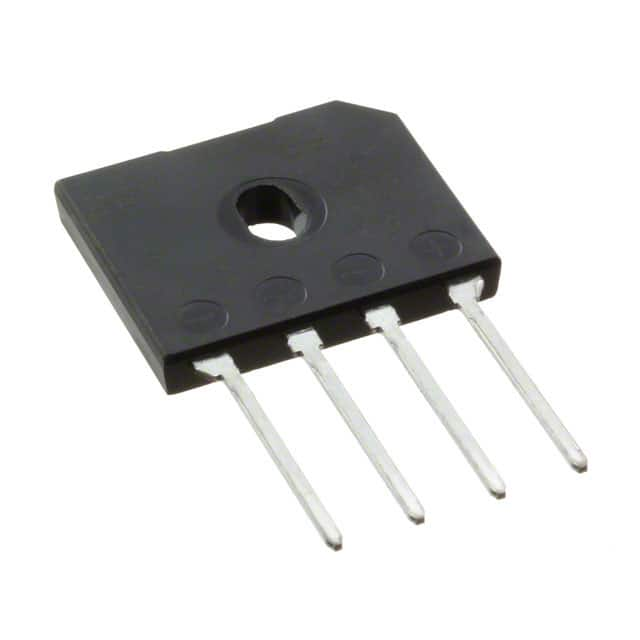

GBU4B Diode Bridge Rectifier

Introduction

The GBU4B diode bridge rectifier is a crucial component in electronic circuits, serving the purpose of converting alternating current (AC) to direct current (DC). This entry provides an overview of the GBU4B diode bridge rectifier, including its product details, specifications, pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models.

Product Information Overview

- Category: Electronic Components

- Use: Converting AC to DC in electronic circuits

- Characteristics: High efficiency, low forward voltage drop, compact design

- Package: Through-hole or surface mount

- Essence: Essential for power supply circuits

- Packaging/Quantity: Typically available in reels or tubes containing multiple units

Specifications

- Maximum Average Forward Current: 4A

- Peak Repetitive Reverse Voltage: 100V to 800V

- Maximum RMS Voltage: 70V to 560V

- Forward Voltage Drop: Typically around 1V

- Operating Temperature Range: -55°C to +150°C

Detailed Pin Configuration

The GBU4B diode bridge rectifier typically consists of four pins arranged in a specific configuration. The pinout configuration is as follows: - Pin 1: AC Input+ - Pin 2: AC Input- - Pin 3: DC Output+ - Pin 4: DC Output-

Functional Features

- Efficiently converts AC to DC with minimal power loss

- Compact design suitable for space-constrained applications

- Low forward voltage drop minimizes energy dissipation

- Reliable performance across a wide temperature range

Advantages and Disadvantages

Advantages

- High efficiency

- Compact size

- Low forward voltage drop

- Wide operating temperature range

Disadvantages

- Limited maximum average forward current

- Requires proper heat dissipation in high-power applications

Working Principles

The GBU4B diode bridge rectifier operates on the principle of utilizing four diodes in a bridge configuration to rectify the incoming AC signal into a smooth DC output. When the input AC voltage alternates, the diodes conduct in sequence, allowing the current to flow in one direction through the load, resulting in a rectified DC output.

Detailed Application Field Plans

The GBU4B diode bridge rectifier finds extensive use in various electronic applications, including: - Power supply units for consumer electronics - Industrial automation equipment - LED lighting systems - Motor control circuits - Renewable energy systems

Detailed and Complete Alternative Models

- GBU4A: Similar specifications with a lower peak repetitive reverse voltage

- GBU4D: Higher maximum average forward current with comparable voltage ratings

- GBU6B: Higher current rating for applications requiring greater power handling capacity

In conclusion, the GBU4B diode bridge rectifier is a vital component in electronic circuits, offering efficient AC to DC conversion with a compact form factor. Its wide range of applications and availability of alternative models make it a versatile choice for various design requirements.

Word Count: 443

Wymień 10 typowych pytań i odpowiedzi związanych z zastosowaniem GBU4B w rozwiązaniach technicznych

Sure, here are 10 common questions and answers related to the application of GBU4B in technical solutions:

What is GBU4B?

- GBU4B is a bridge rectifier diode that converts alternating current (AC) to direct current (DC) in electronic circuits.

What are the typical applications of GBU4B?

- GBU4B is commonly used in power supplies, motor drives, and other industrial and consumer electronics applications where AC to DC conversion is required.

What is the maximum average forward current for GBU4B?

- The maximum average forward current for GBU4B is typically 4A.

What is the peak repetitive reverse voltage for GBU4B?

- The peak repetitive reverse voltage for GBU4B is typically 1000V.

What is the operating temperature range for GBU4B?

- The operating temperature range for GBU4B is usually -55°C to +150°C.

Can GBU4B be used in high-frequency applications?

- GBU4B is not suitable for high-frequency applications due to its relatively slow recovery time.

Does GBU4B require a heat sink for thermal management?

- Depending on the application and power dissipation, GBU4B may require a heat sink for proper thermal management.

Is GBU4B available in surface mount packages?

- Yes, GBU4B is available in surface mount packages for compact and space-constrained designs.

What are the key advantages of using GBU4B in technical solutions?

- GBU4B offers high voltage capability, low leakage, and reliable performance, making it suitable for various AC to DC conversion applications.

Are there any recommended alternative components to GBU4B?

- Some recommended alternatives to GBU4B include GBU4D and GBU4G, which offer similar electrical characteristics and package options.

I hope these questions and answers provide a good overview of the application of GBU4B in technical solutions! If you have any more specific questions, feel free to ask.